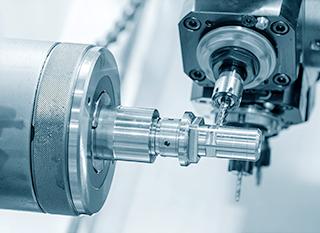

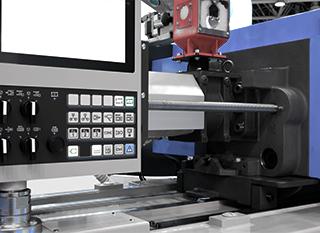

CNC metal cutting and forming

From DIY enthusiasts seeking precision in metalwork to industrial applications requiring efficient production, our company specializes in providing sheet metal cutting services using advanced tools such as laser cutting, CNC sheet metal cutting, water jet cutting, and plasma cutting, ensuring accurate and customized solutions for diverse projects.

45%

Aluminum

15%

Stainless steel

20%

Steel

20%

Others

How we help your business grow

Guarantee

Maximum value

Price

Competitive & Reasonable

Customization

Base on customer preferences

Quality

Never compromise

Delivery

Always on time

24

Quotation in HR

35

Production in DAYS

72

Express service in HR

25

Rush order deliver in DAYS

Briefly explained

How does laser cutting works?

Laser cutting uses a focused laser beam to melt, burn, or vaporize materials along a computer-guided path. The intense heat creates precise cuts with minimal heat-affected zones. This technology is versatile and widely applied in industries for its accuracy and ability to cut various materials.

Bend and cut parts with on-demand delivery

CNC Metal parts bending and forming components

With the integration of metal sheet bending, cutting, and punching into our repertoire, our precision-driven approach extends even further. Proficient across various materials, from metals to plastics, our advanced processes guarantee the prompt production of accurate components. This expanded capability underscores our commitment to providing comprehensive solutions for diverse manufacturing needs

Forming process

We do not just provide parts.

We provide answer and solution.

Sheet metal cutting

Technical data

| Max wallthickness: | 25 mm |

| Min wallthickness: | 0.2 mm |

| Batch sizes: | from 1 piece |

Our materials

Available materials

| Stainless steel series | 300 Series | SUS303, SUS304, SUS304L, SUS316, SUS316L, SUS317, SUS317L. |

| 400 Series | SUS420J2, SUS430, SUS434, SUS442. | |

| Steel Series | Carbon steel | 12L14, 12L15, 1018, 1117, 1141, S1020, 1030, 1040, 1045, 1050. |

| Cr-MO | SCM430, SCM415, SCM435, SCM440. | |

| Ni-Cr-MO | SNCM415, 4140, 4130, 4340. | |

| Aluminum Series | A2011, A2024, A2017, A5052, A5056, A6061, A6063, A6463, A6082, A7075. | |

| Brass Series | CDA3600, CCDA3604, 544, 932. |

Surface treatment

We get the best out of your components

At DMS, we understand that refinement, appearance, and protection against wear and corrosion are essential aspects of our core business. We not only focus on the production of components but also prioritize the refinement and surface treatment of turned parts. Our expertise extends to providing solutions that enhance the aesthetics, durability, and functionality of the components we manufacture.

-

Sandblasting

-

Paint

-

Anodizing

-

Powder coating

-

Electroless nickel

-

Galvanizing

-

Passivate

-

Chromate

Your partner for all components

Other manufacturing processes

Sourcing easier than ever

Perfect components in 3 steps

1

Get a quote

Send manufacturing drawing and specify order. You will receive your quote within 48 hours.

2

Quality control

We find the right manufacturer, monitor production and take care of quality control

3

Receive components

You receive your quality-tested components including a detailed test certificate.

Custom metal parts fabrication experts.

Hear from the real MVPs

Our Customers

Tony Fred, Senior Buyer

Hi Jim, we greatly appreciate the exceptional service provided by you, great good looking CNC parts, which has significantly contributed to the success of our research projects and enabled us to achieve breakthroughs in record time.

Mich Stark, R & D Engineer

Hi Jim, your outstanding service is super impressive. Your great job on our stainless steel bending case makes our espresso coffee grinder added value. It really makes it look nice, super well done.

Aline Turner, SR procurement

We would like to say thank you to you Alice, DMS delivered our parts very fast with excellent quality that is what we are expecting, hopefully you will see our next order very soon, by the way Alice, please say hi to Jennifer for me.

Iris Joe, Engineering Designer

Dear Alice, Now I can say it is a right decision to move our production from China to DMS, you guys are awesome, all the marine pads looks shinny no scratch founded, it is 8% more expensive compare to China but quality talks, we will keep buying more items from you for sure.

We transform your ideas into reality.