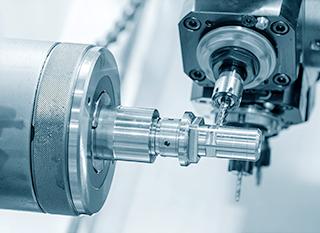

CNC Milling

DMS Group excels in CNC milling, offering precision services from 3-axis to 5-axis. Our state-of-the-art technology, including advanced CNC milling machines, ensures accurate and efficient production. Specializing in high quality CNC milling parts, we guarantee precision from start to finish.

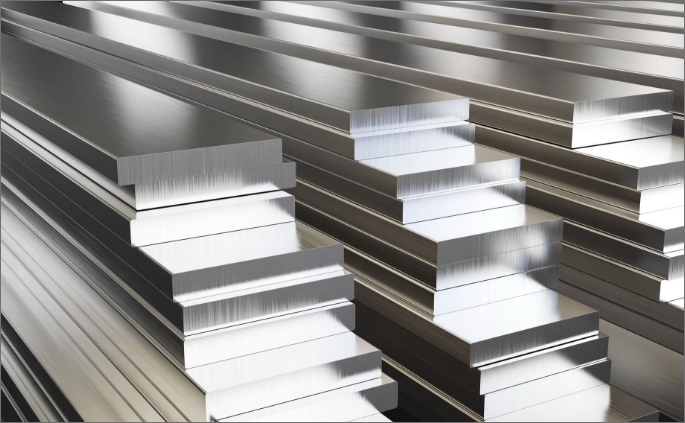

45%

Aluminum

15%

Stainless steel

20%

Steel

20%

Others

Super fast process to produce your CNC milling parts

Rapid Prototyping

Transform CAD designs into final CNC-milled prototypes quickly with DMS. Test and refine your concepts, reduce costly milling errors, and accelerate your product’s time-to-market.

Bridge Production

Seamlessly transition from prototype to CNC milling production. With DMS Bridge Production, ensure smooth transition phases, mitigate risks of scaling, and maintain consistent quality throughout.

Demand Production

Respond to market needs with precision CNC milling on-demand. DMS ensures you meet deadlines, manage inventory efficiently, and produce high-quality components exactly when needed.

24

Quotation in HR

35

Production in DAYS

72

Express service in HR

25

Rush order deliver in DAYS

Milled parts with on-demand delivery

CNC milling of plastic and metal components

DMS offers streamlined procurement, punctual delivery, and adherence to the highest quality standards. Our milled parts are produced using cutting-edge 3-axis and 5-axis milling machines.

We work with a wide range of materials, including aluminum, stainless steel, and plastics, ensuring versatility in CNC milling.

Whether it's precise prototyping, spare parts, or series production, our advanced CNC milling machines and processes enable us to deliver accurate components on-demand, meeting your desired delivery date.

We do not just provide parts. We provide answer and solution.

CNC Milling

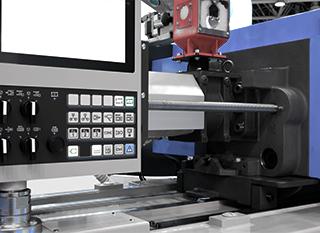

Technical data

| Traverse paths: | X-axis: up to 10,000 mm |

| Y-axis: up to 4,300 mm | |

| Z-axis: up to 1,250 mm | |

| Tolerances: | from +/- 0.005 mm |

| Batch sizes: | from 1 piece |

Explore usable information about steel material

Learn more

Discover more about aluminum material

Learn more

Our materials

Available materials

| Stainless steel series | 300 Series | SUS303, SUS304, SUS304L, SUS316. |

| 400 Series | SUS420J2, SUS430, SUS434, SUS442. | |

| Steel Series | Carbon steel | 12L14, 12L15, 1018, S1020, 1040, 1045. |

| Cr-MO | SCM430, SCM415, SCM435, SCM440. | |

| Ni-Cr-MO | SNCM415, 4140, 4130, 4340. | |

| Aluminum Series | A2024, A5052, A6061, A6063, A6463, A6082, A7075. | |

| Brass Series | CDA3600, CCDA3604, | |

| Plastic Series | EPDM, Delrin, Lexan, Nylon 66, Nylon 6, POM, Peak, PP, PE, Acetal. | |

| Titanium Series | Grade 1 to grade 28 | |

| Magnesium Series | AMS 4375 - AZ31B-O Sheet, plate | |

| AMS 4376 - AZ31B-H26 Plate |

Briefly explained

How does CNC milling work?

Milling is a subtractive manufacturing process where the tool moves into the clamped material at a higher speed and specified feed rate. Modern CNC milling machines gradually remove material from block, plate, or bar materials using milling heads, shaping the workpiece.

The shapes and tolerances are defined by a custom NC program and implemented by the CNC machine. DMS utilizes 3-axis or 5-axis milling machines to process prepared semi-finished products.

With our extensive manufacturing expertise, we can reduces machining and setup times, enhances precision in CNC milling, and significantly improves throughput times, particularly for large quantity production.

Features of 5-axis Control Machines

More flexible machining method that can be done on a machine with three linear axes (X, Y and Z) and additional two swivel rotary axes.

Additional swivel rotary axes enable machining of more extensive areas in one setup.

Machining is mainly grouped into two types depending on how the additional two axes are used, about fundamentals. Learn more

Surface treatment

We get the best out of your components

At DMS, we understand that refinement, appearance, and protection against wear and corrosion are essential aspects of our core business. We not only focus on the production of components but also prioritize the refinement and surface treatment of turned parts. Our expertise extends to providing solutions that enhance the aesthetics, durability, and functionality of the components we manufacture.

-

Sandblasting

-

Paint

-

Anodizing

-

Powder coating

-

Electroless nickel

-

Galvanizing

-

Passivate

-

Chromate

From 0 - 100

Good finish means everything

Our commitment extends beyond production. We meticulously maintain part quality and performance from handling to delivery. Importantly, we understand the significance of packaging in relation to surface treatment, all while prioritizing an earth and environmentally friendly approach. Every detail counts.

Your partner for all components

Other manufacturing processes

Sourcing easier than ever

Perfect components in 3 steps

1

Get a quote

Send manufacturing drawing and specify order. You will receive your quote within 48 hours.

2

Quality control

We find the right manufacturer, monitor production and take care of quality control

3

Receive components

You receive your quality-tested components including a detailed test certificate.

Custom metal parts fabrication experts.

Hear from the real MVPs

Our Customers

Tony Fred, Senior Buyer

Hi Jim, we greatly appreciate the exceptional service provided by you, great good looking CNC parts, which has significantly contributed to the success of our research projects and enabled us to achieve breakthroughs in record time.

Mich Stark, R & D Engineer

Hi Jim, your outstanding service is super impressive. Your great job on our stainless steel bending case makes our espresso coffee grinder added value. It really makes it look nice, super well done.

Aline Turner, SR procurement

We would like to say thank you to you Alice, DMS delivered our parts very fast with excellent quality that is what we are expecting, hopefully you will see our next order very soon, by the way Alice, please say hi to Jennifer for me.

Iris Joe, Engineering Designer

Dear Alice, Now I can say it is a right decision to move our production from China to DMS, you guys are awesome, all the marine pads looks shinny no scratch founded, it is 8% more expensive compare to China but quality talks, we will keep buying more items from you for sure.

How we help your business grow

Guarantee

Maximum value

Price

Competitive & Reasonable

Customization

Base on customer preferences

Quality

Never compromise

Delivery

Always on time